The 2024 Sweet & Snacks Expo, hosted by the National Confectioners Association, returns with a theme that’s more “Big & Bold” than ever before. The trade show will take place at the Indiana Convention Center in Indianapolis from May 14-16, bringing together thousands of manufacturers, retailers and suppliers in the confectionery and snack industry for unique insights, cutting-edge product innovations, and powerful connections.

The 2024 Sweet & Snacks Expo, hosted by the National Confectioners Association, returns with a theme that’s more “Big & Bold” than ever before. The trade show will take place at the Indiana Convention Center in Indianapolis from May 14-16, bringing together thousands of manufacturers, retailers and suppliers in the confectionery and snack industry for unique insights, cutting-edge product innovations, and powerful connections.

Bell Flavors & Fragrances, Inc. will join nearly 200 exhibitors at the Supplier Showcase from May 13-14 and hit the Trends & Innovation stage alongside presenters during eight must-see education sessions.

Join Vice President of Marketing & Industry Affairs Kelli Heinz and Senior Director of Marketing David Banks as they hit the Trends & Innovation Stage on May 15 at 1 pm ET and May 16 at 11 am ET to reveal Flavor Trends in Confections. This discussion will explore novel and soon-to-be-big trends in confectionery, with a focus on global and regional consumer behaviors influencing these trends and how different generations respond to new flavors in the marketplace.

Trends we are seeing this year encompass products that play off popular culture fads and a return to the classics,” Banks said. “These provide consumers a small indulgence or sense of security that comes from enjoying the regional and nostalgic treats from their youth.

“At the heart of confectionery trends lie two core elements – renovation and innovation. Whether it’s renovation of the classics to make products better for you with cleaner label ingredients, colors, and added benefits or innovation by adding a modern twist or brand partnership, the industry has the key ingredients to drive consumer engagement.”

For more information on this must-see session, click here.

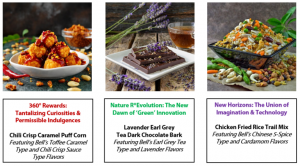

Attendees will have the opportunity to engage in five tastings, each spotlighting one of Bell’s five global consumer Macro Trends as part of the Spark–Ignites Creativity, Inspires Senses Platform:

t’s always a treat to present Bell’s Spark Trends to the attendees of the Sweets & Snacks Expo.” Heinz said. “Our Spark Trends platform not only identifies what’s up and coming for flavor trends, but identifies what’s at the root of Macro and Micro trends impacting the confectionery industry as a collective whole. Each Macro trend presented will be supported by a unique tasting, so be sure to catch one of the presentations!”

Bell joins nearly 200 exhibitors at the Supplier Showcase on May 13 from 1-5 pm ET and May 14 from 9 am – 1 pm ET. Attendees can visit Bell Flavors & Fragrances at booth #3405 to explore innovative flavor trends and discover taste technology solutions (e.g., sugar reduction, flavor masking) that elevate confectionery, bakery, ice cream and savory snack portfolios. Bell’s cross-functional experts, including Sales, Sweet Applications and Marketing, will be onsite to discuss a tailored approach to pushing product development boundaries with taste.

To schedule an in-person appointment with our experts in advance of the show, reach out to info@bellff.com.

Bell Flavors & Fragrances, Inc. is a leading supplier of flavors, fragrances, botanical extracts and ingredient specialties to the food and beverage industry, as well as the household care and personal care industries, offering over 110 years of exceptional customer service and experience. Bell has 11 manufacturing plants worldwide including the United States, Canada, Mexico, Colombia, Brazil, Germany, India, Singapore, and China, with sales offices in more than 90 countries. Bell’s global presence allows flexibility in the world marketplace while constantly responding to emerging industry trends with solutions that bring added value and business opportunities to our customers.

For more news of interest to the food and beverage industry, subscribe to Gourmet News.